for Gas Monitoring in parking garages, tunnels, engine repair shops, loading bays, engine test benches, shelters, go-kart race courses etc.

Carbon Monoxide (CO) Gas Detector GCO for wall mounting

• Output 4-20 mA or 2-10 Vdc

• Power supply 24 Vdc

• Ranges:

GCO 100 have range 0-100 ppm

GCO 300 have range 0-300 ppm

• Sensor element electrochemical

• IP65 enclosure with quick locking screws

• Digital measurement value processing including temperature compensation

• Internal function control with integrated hardware watchdog

• Data / measured values in micro controller of sensor unit,

therefore simple exchange uncalibrated <> calibrated

• High accuracy, selectivity and reliability

• Low zero point drift

• Hardware & software according to SIL2 compliant development process

• Easy maintenance and calibration by exchange of the sensor unit

or by comfortable on-site calibration

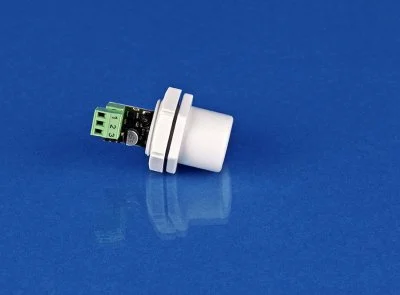

Carbon Monoxide (CO) gas sensor with PCB

Normal life time is 6 years for Carbon Monoxide (CO) gas sensor.

The Carbon Monoxide (CO) gas sensor with PCB

can easily be exchanged after 6 years.

Special filter for IP65 protection of Carbon Monoxide (CO) gas sensor

Duct Mounting Set DMS 300G

for sensing Carbon Monoxide (CO) gas in ventilation duct

The Duct Mounting Set DMS 300G includes:

• 300 mm long duct probe with neoprane gasket on the duct flange

for good sealing into the duct.

• 2 x 1 meter silicone hose.

• Plug-connector to the Carbon Monoxide (CO) gas sensor head.

Duct Mounting Set DMS 300G assemblied with

Carbon Monoxide (CO) Gas Detector GCO

Design Features

Exchangeable Carbon Monoxide (CO) gas sensor unit GCO including digital value processing, temperature compensation and self control for the continuous monitoring of the ambient air.

The Carbon Monoxide (CO) gas sensor unit GCO houses a module with a micro controller, analog output and power supply in addition to the electrochemical sensor element including amplifier.

The micro controller calculates a linear 4-20 mA or 2-10 Vdc signal out of the measurement signal and also stores all relevant measured values and data of the sensor element.

Calibration is done either by simply replacing the sensor unit or by using the comfortable, integrated calibration routine directly at the system.